- +91 7742004780

- info@kkengineeringindia.com

- ISO 9001:2015

- Mon - Sat 9:00 AM - 7:00 PM, Sunday - CLOSED

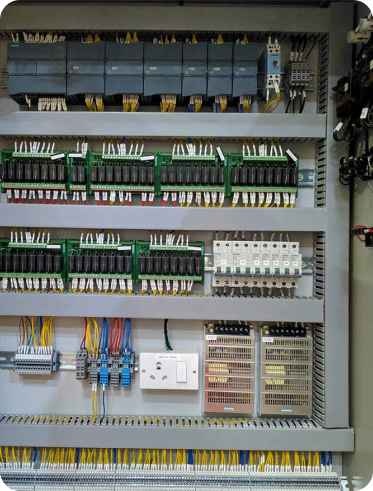

Electric panel processes the input taken from the sensors like photo and reed sensors and controlls the machine accordingly.

Electric Panel is responsible for the safeguard and the protection of the machine.

It has various electric and electronic components embedded in it. These components consists of VFD, Motors starters, PLC, DBR etc.

KK Line Polishers has many safety components to ensure the safety of the machine as well as of the machine operator.

Maintenance friendly features Reed Sensors are used in every pneumatic cylinder (2 sensors per head) to detect the height of the head, they help operator to know if the head's bricks require replacement or replacement or not. Safe Warning makes it easy for the operator to know the requirment of the oil in heads. Greese tank and FRL are used to supply grease to the machine and FRL filters the lubrications.

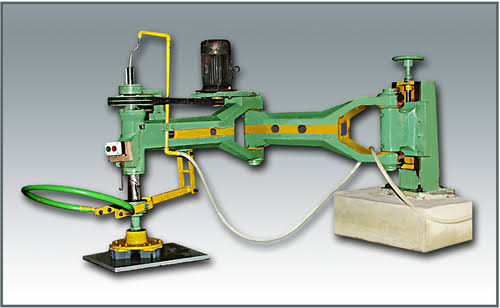

In KK LPMs gang rollers are used instead of the tradition linear guides (L.M.). gang rollers requires less Maintenance than the L.M. The lifetime of the bridge Reciprocating motion increases eightfold because of these gang rollers.

| Name | Value |

|---|---|

| Heads | 4 - 22 |

| Heads type | Flicker/disc |

| Control panel | PLC controlled |

| Conveyor speed | 0.3-1.5meter/minute |

| Bridge speed | 0.3 – 35meter/minute |

| Profile sensor | slab thickness sensor |

| Name | Value |

|---|---|

| No. Of heads | 1 |

| Head type | flicker |

| Control panel | INTERLOCK |

| Name | Value |

|---|---|

| No. Of heads | 3 - 12 |

| Head | 26” disc |

| Conveyor speed | 0.3-1.5meter/minute |

| CONTROL PANEL | INTERLOCK |